Gibson guitar factory

During my recent trip to Memphis, Tennessee I finally had the opportunity to tour the Gibson factory. The factory itself was mostly shut down as it was around the New Year so – for the most part – I couldn’t see guitars actively being created; however, the tour guide explained every step of the way in great detail.

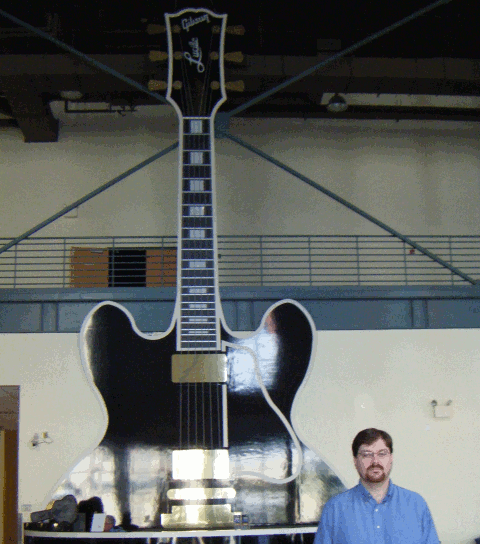

All of the semi-hollow body guitars are made at the Memphis location as well as two of the solid body guitars (including a double-necked model). Their other guitars are made in Nashville, Tennessee and Bozeman, Montana. The factory is highly decorated and has a large guitar model, photographs of famous musicians with their guitars, and a hallway of display guitars as well as a store front where you can see even more guitars – or purchase one. The prices start at $400 and go up from there. The store is also where tickets for the tours may be purchased.

The process involved in making these guitars are much more remarkable than I imagined. Each guitar is hand made to exacting specifications and takes between two and three weeks to produce. The finished product cannot be more than 1/64th of an inch off of specifications or it is destroyed; no guitar is sold unless it is nearly perfectly constructed. Considering that they are all hand-made, I expected that many guitars would have to be scrapped for being out of tolerable range, but – it turns out – only about two or three out of every 1000 of them actually have to be destroyed. That is much less than 1%.

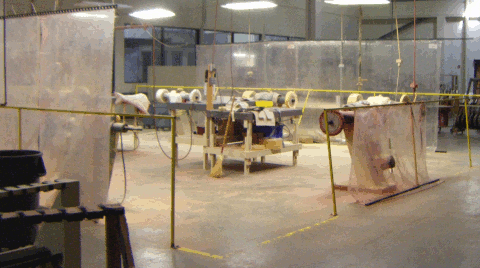

The creation of a guitar takes so long because of the numerous steps involved. In fact, there are so many that I cannot enumerate them all here, but I will list a few of the more major ones. The wood for the body is placed in a humidity chamber until it is completely saturated to allow it to bend without breaking. Then the wood is curved and put into a press to hold its shape until it dries. The sides, front, back, and neck are glued together. The guitars are painted and lacquered. Finally, the guitars are buffed to become the beautiful finished products you see on display in the hallway and the store.

If you have an hour and $10, I would highly recommend taking a tour. There is too much information – including the history of the company and its founder – to cover in a short blog post. And, even if I could, this really is one of those things you have to see for yourself.